In 2020, global data centre spending reached $37 billion, with Amazon, Google, and Microsoft accounting for more than 50% of this. Data centres are facilities that can centralise the shared IT operations for an organisation, making it easier to store, process, and disseminate data.

They are a vital component for the daily operations of many businesses and provide organisations with many more benefits.

Do you want to learn more about data centre automation and data centre services in the UK? Keep reading this article for the top six benefits of using data centres for your business.

1. Security compliance

One of the primary benefits of using data centres for your business is that they offer improved network security and compliance. Colocation centres offer many security features to keep your data safe, including key cards and other types of regulated entry.

Plus, using a local colocation centre allows you to check on security yourself. You can gain access to your servers to make sure everything is in working order.

Not only do data centres offer high security, but they can also protect your business from cyber threats. They can offer network security including firewalls and other systems that can protect your data from unauthorised access.

This is especially important if your business deals with private or confidential data, as your customers will be confident in your ability to protect their information.

2. Room to grow

Next, using data centres for your business gives you room to grow. As time goes on, your business needs will continue to change. By using this technology for your business performance, you can match your needs as your business grows.

Using a colocation data centre allows you to expand your business infrastructure without having to spend a fortune.

If your business grows, your IT infrastructure can grow with it. This scalability makes using a data centre a great option for new small businesses.

3. Improved connectivity

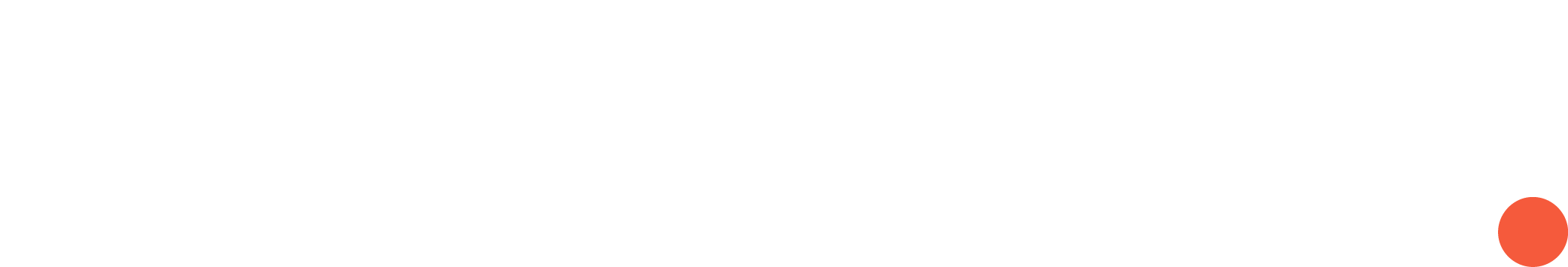

Another great benefit of using data centre services in the UK is that it offers better connectivity for your network. When you are running a business, having a network problem can cause serious issues with your productivity and business performance.

However, colocation data centres utilize redundant network connections to prevent connectivity issues. This means that your businesses important applications can always run smoothly without interruption.

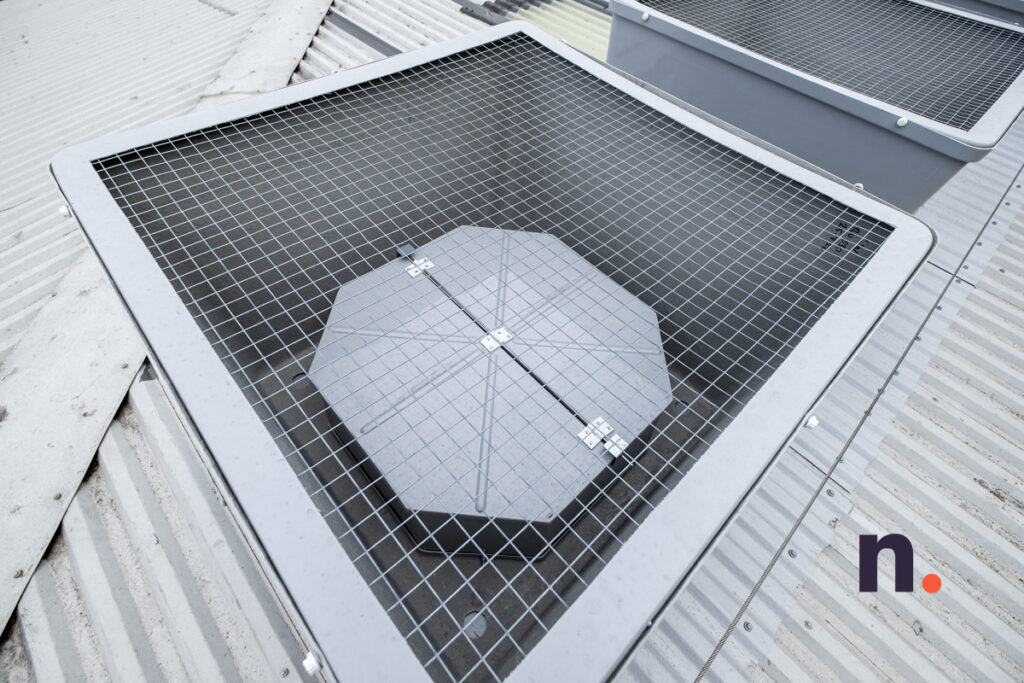

Data centres also offer power redundancy. They use several different power grids, generators, and even backup battery systems to ensure that you will never lose connection, even when the power goes out.

These factors, combined with regular maintenance of the data centres, ensure that you will always be able to access your data.

4. Data mobility

Across the world, it is estimated that 52% of employees work from home at least once a week. Because so much business is done virtually, especially after the global pandemic, businesses need to be able to access their data no matter where they are. Using a virtual data centre provides your business with data mobility.

This means they will be able to access IT workloads and business data no matter where they are or when they need access. With this data mobility, your business can run and manage its workload on the cloud.

Because remote work is becoming one of the biggest benefits an organization can offer to its employees, it is vital that businesses also make the change to business mobility.

Similarly, using colocation data centres allows your company to take steps toward cloud migration. While the transition to cloud computing can be overwhelming, having your equipment in an offsite facility will help the process to go more smoothly.

5. Increases productivity

When you use data centres for your business, it also enables you to increase your productivity. When you have issues with your IT services or network downtime, it is often due to human error.

Because data centres allow for true automation, it takes out the possibility for manual error. It also saves you hundreds of hours in managing your resources.

This is something that can greatly lower your operational expenses and make it faster and easier for you to access your IT services.

Similarly, using a data centre provides you with more control for your business. You do not have to risk giving up control of your data if your network has a cyber threat. You will also not have to worry about having your systems shut down without warning.

Utilizing data centres for your business acts as prevention for these problems and can save you countless hours by preventing data disasters.

6. Cost-effective solutions

Finally, data centres and colocation service providers are cost-effective solutions for any business owner. The cost of IT infrastructure is continually increasing and inflexible. Many companies worry about being locked into inflexible infrastructures.

Plus, increasing your IT infrastructure as your business grows can be a costly investment. Instead, businesses can grow at their own pace when using a data centre.

This allows you to maximize your profitability and to have more control over your business costs, management, and more.

If you are looking for a way to save money for your business, you can talk to your local colocation service providers to learn more about their data centres.

Looking for data centre services in the UK?

Utilizing data centres for your business is a simple way to improve your data security and mobility cost-effectively.

If you are looking for colocation service providers in the UK, we can help! Our team is the UK’s leading colocation service provider and offer private facilities in the centre of London.

Contact our team today to learn more about our data centre services or to book a tour at our data centre locations in the UK.