Visual updates have been somewhat limited throughout January, hence the delayed publishing of this five week instalment of the Build Blog.

The bulk of time and effort on-site is still being spent on end-out plans, and getting the energisation works underway. Alongside this, we’ve also been carrying out supplementary works in a number of areas, to keep things progressing while time is spent on final stage plans.

Weekly overview

In terms of physical on-site work, we’ve been keeping tempo with a range of works across a number of areas, all of which have helped to keep visual progress steady (but comparatively limited) while the next phase is executed behind the scenes.

Because visual change is somewhat limited at the moment, we have a lesser number of photos available in this instalment, however they do show various changes and arrivals throughout the site.

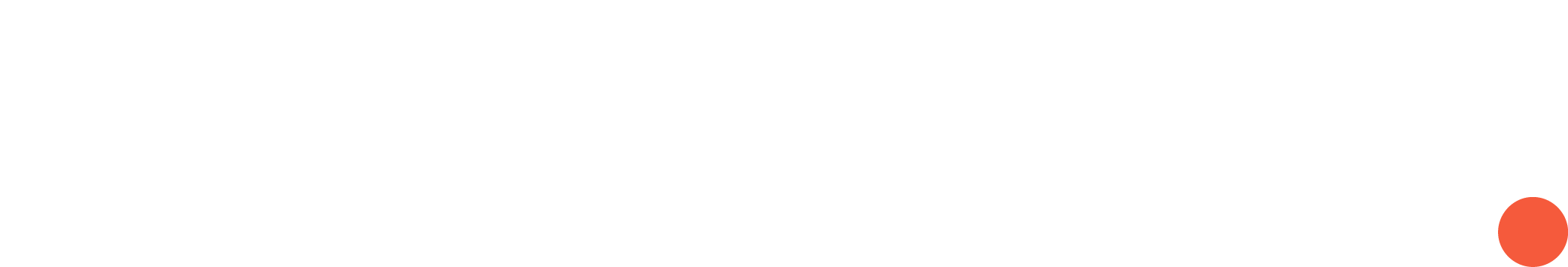

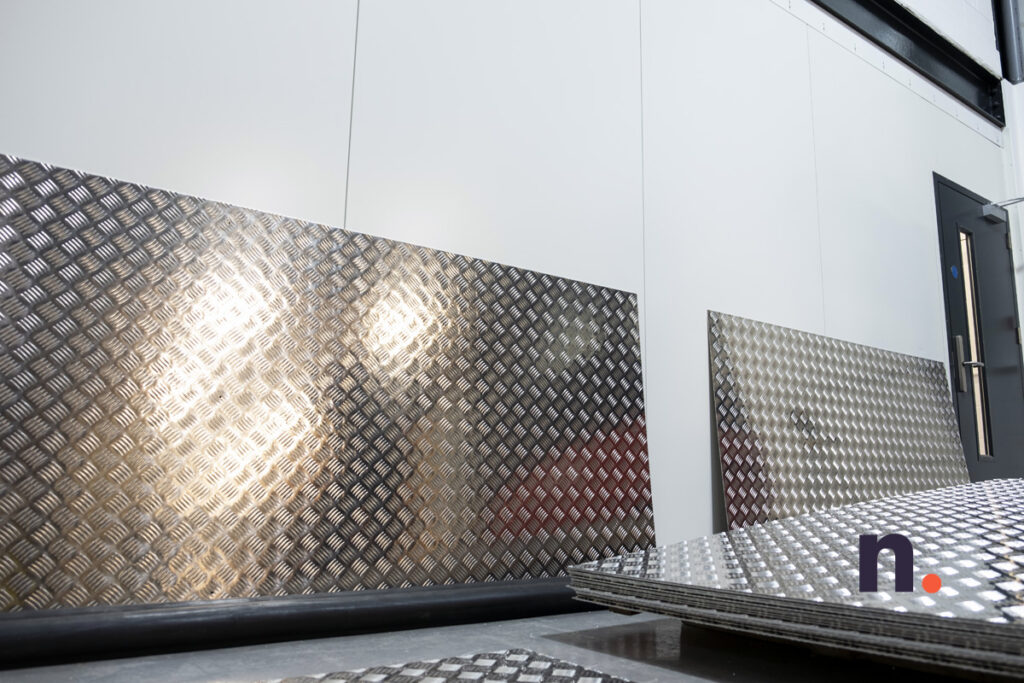

The ground floor areas that were due checker plate cladding as part of the phase one roll-out have now had all areas completed, aside from a couple of missing sheets; we’re now waiting on additional material to arrive with us. This will also allow for checker plating and associated bash protection to be installed in the loading bay, where equipment will be lifted to each level loading dock for both the ground and first floors.

The ground floor has also had its final lighting systems cabled and energised, meaning that all site lighting can now be removed – a great milestone in terms of this becoming a self-supported utility it its final guise.

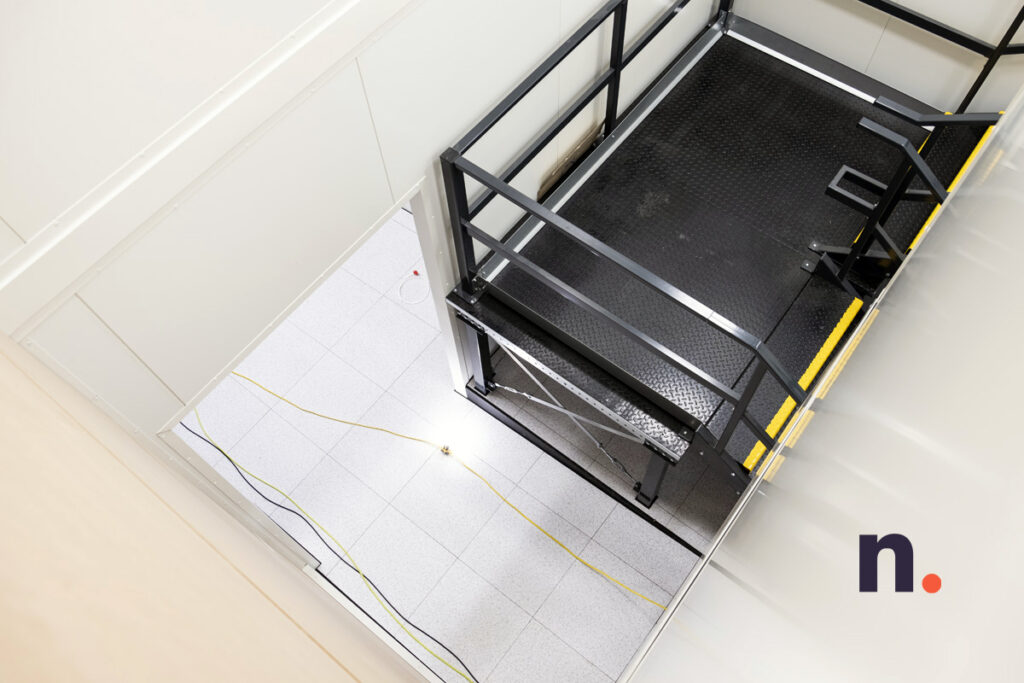

The main front-of-building turnstile came back to us late last year, having been to our powder coaters to ensure a match with the existing system at London Central. This was installed towards the end of 2020, however has yet to have its internals fitted to the overhead containment tray. This will be done when weather permits, given the current snowy state of the UK earlier this week!

Some of our new electrical boards have started arriving on-site. These are largely our new Mardix units, which have been built in a number of varieties depending on the end use case, and delivered in our signature orange. These really pop against the otherwise monochrome data halls, turning out just as we had planned. The larger of the two orange board types each hold a self-contained ATS to allow for dual incoming feeds for all critical M&E equipment.

Most of the VESDA equipment is now on-site, aside from the red pipework that will be installed to collect the air samples. This forms part of the final fire protection plans, which are being completed in the next couple of weeks.

You can also see that our comms panels (ODFs) from Ortronics have arrived, which will be used to handle and distribute fibre from each A and B core. These will be installed as part of the network roll-out at London East, which is set to begin later in this final stage of works.

We’ve also had a team up on the main roof this week, however things were postponed slightly due to adverse weather. Despite there being no issues with the roof, we’re electing to have the roof resealed for our own peace of mind; something we did at London Central also. This will lead onto roof and skin adjustments for apertures in due course, both for personnel access and our cooling system.

What else has been happening?

The bulk of progress in January has definitely fallen into the ‘else’ category when it comes to the Build Blog, as the vast majority of time continues to be spent on desk work, bringing together the final elements that will enable client services to go live at NLE.

Those elements include LV and HV electrical, which form the bulk of the end-out process. The transformer equipment and the generators fall into this work category, which were ordered this week. We’re very excited to share the delivery of these items as they begin to land with us!

We’ve also finalised plans for everything on the fire protection side of the project, which will be installed concurrently with the main power systems.

Excitingly, we’re also having some really interesting conversations with organisations interested in taking space from day one. These range from simple DR services to support primary systems elsewhere, through to full private pods, custom designed to requirement.

What’s next?

We have a very large shipment arriving with us soon, holding all of the containment for the first pod of racks in Data Hall 1 – this is something we’ve been excited to receive for some time, and equally something we’re very excited to share with you here.