Colocation services allow you to share the resources of a data centre with other businesses, without having to invest in your own private space. The cost of your organisational IT is something that you always have to consider.

As with any professional business service, choosing the cheapest option is probably a bad idea, however it’s important to explore all options to ensure you’re paying fair rates that provide solid value to your business.

Here are some things to think about when measuring and deciding on your colocation costs.

Aligning colocation costs with your needs

There are several benefits to colocation. Alongside the clear benefits, there are a number of factors that you’re best keeping in mind as you begin to explore such a service:

1. Make sure you choose the best colocation company

Focus on quality over everything else. If you find the best colocation company in your area, don’t let price be a serious deterrent unless they’re charging outrageous fees that strip the value out of the service.

Not every data centre is put together to the same high standards. With the build and ongoing operational costs of a data centre being so high, an immediate red flag during your enquiries would be a bargain discounted rate, which is either being used to hook you in, or is a sign of problems with the facility and/or it’s operation.

The best colocation companies in their industry set the market, so finding out what they charge will also give you an idea of the going rate. Get referrals to make sure that you’re choosing the most competent professionals with the highest quality infrastructure.

A few of the things that you’ll need to look for when taking a colocation service include network carrier and power delivery redundancy, service flexibility, a capable support team, and physical security measures that keep the critical infrastructure secure.

2. Shop for the right fee structure

Aside from the rates themselves, you should also consider a colocation operator that offers a payment structure that works for you. Colocation rates can often be billed very flexibly, from monthly, quarterly, annually, or even by the hour in some unique use cases.

You should also find out whether they lock-in the prices for the contract term or whether the contract is revised on different time frames.

3. Figure out which hardware you want to buy

Buying your own hardware is one way to fully align your costs to your needs. Some colocation companies can also organise leasing agreements for you to rent equipment as needed, if an outright purchase is not possible.

Leasing or renting kit is great for many reasons. For example, you don’t have to pay the full price for the equipment upfront, and only pay for what you need. Under this sort of agreement, you can get top of the line, brand new equipment based on a recurring monthly rate, rather than a full, upfront capital investment.

However, it’s worth noting that these agreements do require you to keep paying well after you’ve exceeded the value of the hardware. Depending on your needs, it might be better for you to buy your hardware outright, rather than paying for it each and every month.

This is especially helpful if you are able to get a good deal on some hardware by getting it on discount or refurbished. You’ll need to figure out what makes the most sense for your company and align those needs accordingly.

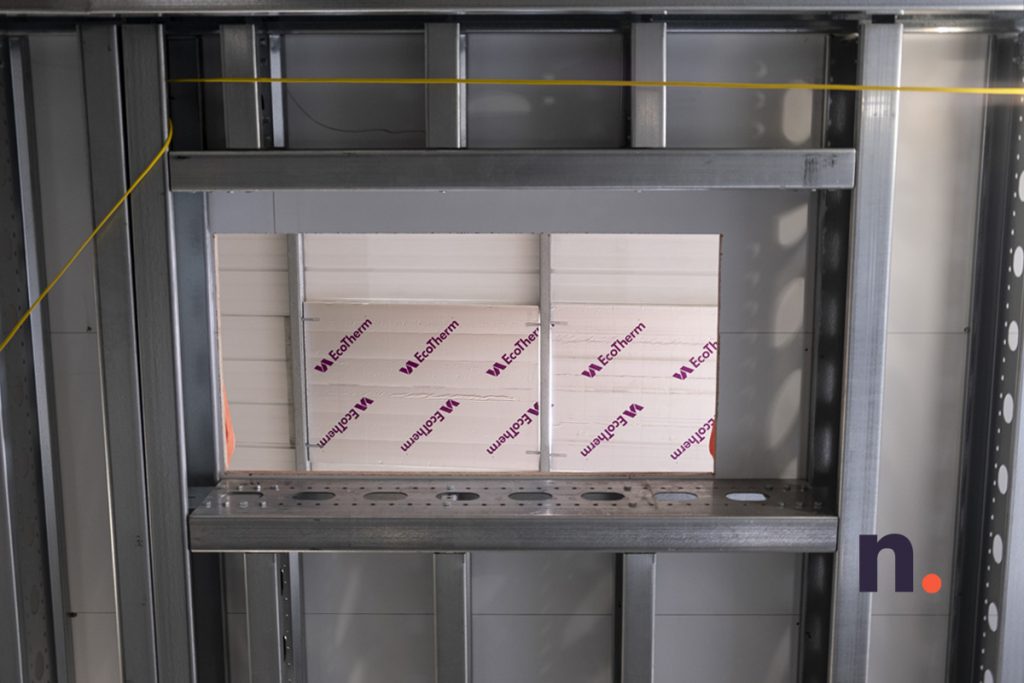

4. Assess the rack capacity

When you’re looking for server colocation services, you need to figure out how much rack space you need to house your equipment.

You’ll then be able to correctly specify how much space you need to house your kit, without over-committing to more (or less!) space than you need, which will keep the costs properly aligned with your requirements. You can then scale upwardly when it’s time to expand.

5. Pay attention to cyber security measures

Always educate yourself on the latest cyber security measures to keep your company well-protected.

Without question, cyber security breaches can end up costing you lots of money. A single breach can cost your company a lot to get back up and running, and even more in any relevant fines from controlling bodies.

Ask the colocation provider what kinds of security they have in place for you, and which areas will need to be factored in by yourself.

Many of these data centres also have emergency plans and policies laid out that will help stem the bleeding if you do happen to get breached. This saves you the time and money of having to figure things out on your own and also helps to eliminate mistakes.

Cost-effective colocation services

Handle your colocation costs with care and consideration, taking note of the tips above. By following these handy pointers, your company will have a greater chance of success in employing use of world-class colocation services.

We can help you with any of your colocation needs. You can get in touch with us online, or by calling 0845 430 9900.