The internet is used by more than 4 billion people worldwide.

The UK makes up for 60.3 million of these internet users, Great Britain bringing in 46.6 million as of 2016. That’s 92.6 per cent of our nation’s population; and growing.

We in London spend large chunks of our days on the internet, amplified further at the moment by the current COVID-19 restrictions. Whether it’s viewing our feeds on social media, sending work emails, video conference calls, uploading files, sending messages, downloading information, or simply surfing the web, data centres in London are working rigorously to transfer this information from one sector to the next.

Simply put, it’s fair to say that the majority rely extremely heavily on the internet.

We spend a lot of our lives online, and yet the environmental impact caused by our heavy use of the internet is commonly overlooked.

As we increasingly become more digitalised, the internet continues to play a key role in our lives. As such, there comes a time in which we must address the effect the internet has on the environment. There’s no doubt the internet requires a massive amount of energy to operate, so how can we remedy the effects of our carbon footprint? Where do we begin to address these effects?

It all starts at the data centre.

The internet in tangible form – data centres

It’s easy to fall short in understanding just how the internet requires so much energy due to its “invisible” nature. Nevertheless, there are four main areas that drive the digital world; devices, networks, manufacturing, and data centres. The latter being of tangible form and largely contributing to the egregious energy consumption the internet partakes in.

Think of a data centre as you would a modern-day factory. They are physical facilities that function as large scale communication hubs and centralised computing facilities. These buildings can essentially be viewed as a collection of specialised computers, known as servers. These computers house a wide variety of things, including databases, websites, communication platforms, AI systems, and much more.

In short, data centres are the internet, materialized. They are the closest thing to the internet in physical form and they are one of two main components of the internet that contribute to having a very notable impact on the environment.

Why do data centres consume so much energy?

Think about data centres as you would your own personal computer. Your computer generates heat when in use. This heat is that energy. You know you’re generating a lot of heat when you hear the fans in your computer start to hum. Now imagine this but on a much, much larger scale. Millions of these specialised computers, known as servers, which are often many times more powerful (and power hungry) than your average home computer.

As a result, more than 4 billion individuals indirectly contribute to the IT sector’s energy consumption, which equates to 10 per cent of all energy consumption worldwide. This number is on continuously on the rise as we become more and more digital. It’s predicted that this number could increase to as much as 33 per cent by 2025.

Because of your indirect contribution to this consumption through use of your various digital services and platforms, a fair part of your carbon footprint comes from the operation of data centres. As an end-user, you have no input regarding what kind of energy your indirect data centre operators are purchasing and using.

So, what is there to do?

The future of internet sustainability

Thankfully, we’ve too found ourselves in a collective cultural transition into renewable energy and the IT sector has followed suit – in fact, it’s lead the way in pervasive use of renewables. As society has shifted to having more concern for our impact on the environment, corporations have also looked to shift towards sustainable energy.

Data centre operators have been racing towards a completely renewable internet for quite some time. Not only is this change great for the environment, it’s also advantageous from a financial standpoint; sustainable energy is consistent in its nature, and therefore holds great value for companies and investors.

‘Going green’ has become standard in terms of what business are looking for when choosing a data centre partner. Because of this, modern internet companies are now actively pursuing green, more sustainable providers to partner with on a long-term basis. Finding a truly sustainable data centre operator in the centre of a city like London can be tough, but they are

Sustainable data centres In London

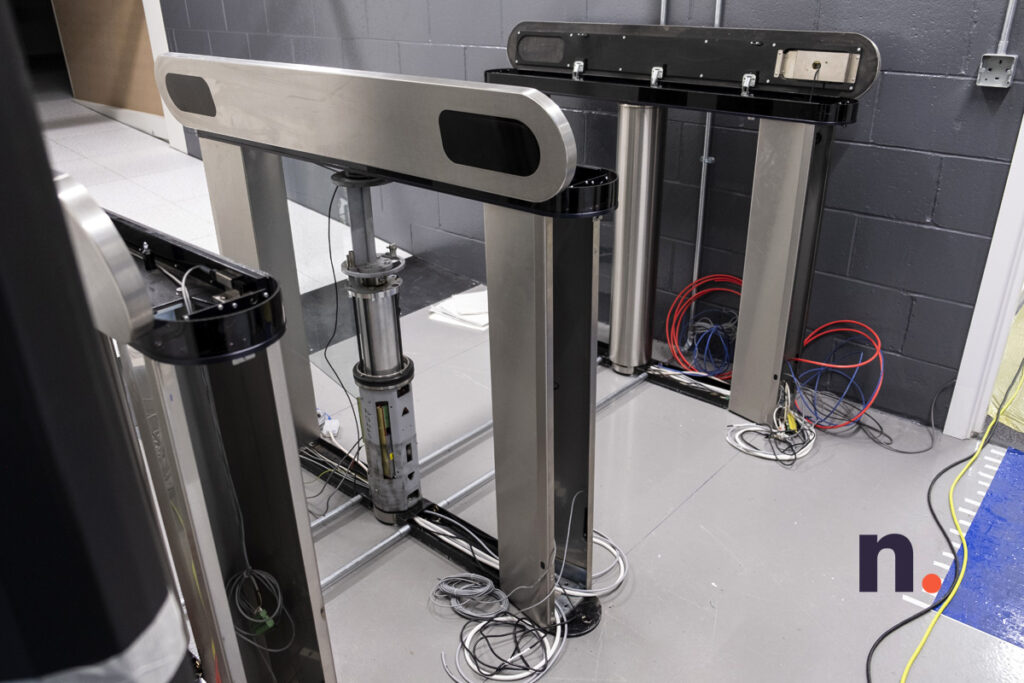

We at Netwise want to be a part of the solution, in creating sustainable data centres to house critical business systems here in London. We do so currently as the UK’s leading colocation and data centre service provider, delivering end-user content on a global scale. We’ve been able to put together two sustainable data centres right in the heart of London, with our third centre in London East coming in 2021.

Our London Central facility uses 100 per cent renewable energy. We aim to be a part of the solution. We aim to keep London sustainable and set the standard for corporations to follow. This enables the reduction of carbon footprint concerns for you as an end-user, as we lead the way in reducing data centre power consumption in the capital.

London East is the next chapter in our journey. We’re taking note from our London Central facility, amping up to a facility with 256 racks, and of course remaining 100 per cent renewable in our purchase and consumption of energy.

Our mission is to provide world-class data centre facilities in enviable locations, while always operating on 100 per cent renewable energy. Our data centres are some of the greenest in all of Europe, powered by energy sourced from the wind, sun, and sea, ensuring you enjoy services with a reduced carbon footprint.

So we ask you, why not come and be part of the solution? Feel free to get in touch or schedule a tour at any of our facilities, or check out our blog for more detail on our upcoming data centre, London East.

London deserves this. London deserves sustainable systems to be put in place and so does the world. We cannot fall short and disregard the invisible nature of the internet. Together, let’s be part of the solution and never the problem.