The colocation data centre market is worth over $54.8 billion. It continues to grow thanks to an increasing global reliance on technology and the related need to increase the scale of IT services in general.

Managing technology requires time, money, and effort, especially when businesses attempt to create solutions in-house. Server colocation allows you to share space with other tenants in a centralised location, which is remote from your office(s). Professionals manage the equipment and network for you, keeping it safe and providing the right environment.

What is server colocation?

Server colocation allows you to share data centre space in a centralised, remote location. It provide businesses with space to install necessary IT equipment while also preventing operation or technical limitations and allowing you to control costs, support, uptime, and security.

What a colocation data enter does

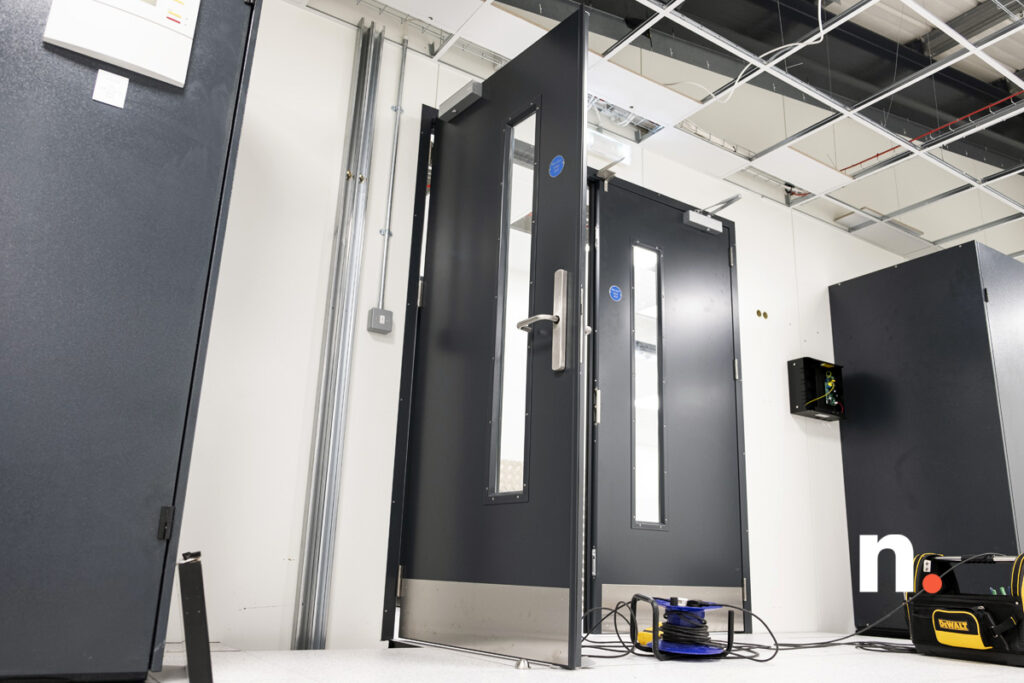

A colocation centre is a physical location that stores data and IT infrastructure on behalf of businesses, and in some rarer cases, individuals. Services include power, cooling, physical security, network connectivity, and resiliency.

These centres offer different types of services as well, allowing you to customize your size and power usage based on your needs.

Types

Wholesale colocation is best for large corporations and service providers. Your space is separate from other tenants, which increases security. Space is sold in square feet or based on total available power, and your price depends on your power and space requirements.

Retail colocation is best for start-ups and SMEs. It provides a turnkey solution that allows you to get set up quickly by providing racks, power, PDUs, network connectivity, and IP addressing. Businesses lease space and receive power at a threshold. Your fees are based on your space allocation and power / network consumption.

Space can be sold in rack units, abbreviated as U. It measures the thickness of each server at 1.75″.

1, 2, or 4 unit colocation is abbreviated as 1U/2U/4U. It involves purchasing individual unit allocations but can be upgraded to include more space. 1U is small and considered entry-stage. The others are somewhat larger, but major businesses may require quarter, half, or full racks for housing more substantial systems.

Quarter rack location offers 10U of colocation space. Everything is stored in a private, locked cabinet. It’s a great option for small businesses and start-ups.

Half rack location is a mid-range option that offers 20U of colocation space and power feeds of 2-8 amps at 240v. It costs £299.00 – £479.00 per month. Lockable, segregated racks provide extra security. There are multiple connectivity options to fit your needs.

Full rack colocation provides a full rack or 42U of cabinet space. It offers more available power and is best for companies with larger IT systems. Multiple racks then allow these systems to be extended, with no upper limit on how many racks can be deployed as part of a single (or even split) system.

Benefits of server colocation

Businesses that aren’t using server colocation create in-house facilities instead. They provide more internal access and control but are complicated and expensive to set up, increase hiring costs, and can decrease uptime.

Colocation centres have several benefits. They increase efficiency, decrease energy consumption, are flexible and scalable, increase security, decrease downtime, and help you manage your budget more closely.

Colocation centres consider both network and physical security. They create several layers of security and threat detection to protect your network. They also monitor the location itself using CCTV and 24×7 on-site personnel.

Colocation centres offer predictable operational expenses. They offer regular fees for rack units, power, and bandwidth. Additional consulting or hardware resources may be part of your service fee or cost extra. Once you know these costs, you can find the total and work it into your budget.

A colocation centre should also be clear about what you don’t have to pay for. They can save you money in several areas, including hiring, power, and heating and cooling costs.

Server colocation is also a way to ensure you don’t lose profits from IT services that aren’t working like you need them to. The true cost of IT downtime depends on several factors, including the duration of the outage and the number of people impacted. It costs businesses an average of approximately $5,600.00 per minute and $140,000.00 – $540,000.00 per hour.

These are only some of the benefits of server colocation. As long as you choose the right provider, you could experience even more positive changes by placing your IT equipment in the hands of professionals.

Choosing server colocation

There are over 4,740 server colocation centres throughout the world, including at least 273 in the United Kingdom. Choosing the right one from this range of options is easier when you know what to look for. Consider factors such as space, power, connectivity, security, support, and price.

Determine how much space you need by looking at your power and infrastructure requirements now and in the future.

There are several ways to ensure you get the best price. Avoid bargain discount rates because they generally indicate poor service. Look at the prices of other server colocation centres in the area. Get referrals online or from trusted friends and family. Choose the best fee structure for you, whether that’s monthly, quarterly, annually, or hourly. Consider if you need to purchase or lease equipment.

There are also some questions to ask before choosing a server colocation centre. Learn more about their:

- Security measures

- Reliability

- Flexibility

- Data capacity limits

- Support team

You can also look online to check the provider’s reputation. Look for their uptime and security records and check their certifications and history of audit compliance.

The typical server colocation contract lasts 1 – 3 years. Be sure you’ve chosen the best provider before signing anything.

Finding the best server colocation provider

Server colocation is one of the newest and most effective alternatives to in-house IT centres. It connects you with professionals to ensure your systems are secure and stay online.

Choosing the right colocation centre is a matter of considering your current needs and how your business will grow in the future. Find an affordable, scalable option that will adapt to your changing IT structure.

Netwise provides colocation services you can trust. Contact us today to find the right solution for you.