This week has seen modifications made to the external skin of the building, with the installation of our custom made louvred panels. These will allow our building to ‘breathe’ once the cooling system is operational, with the flow of air carefully monitored and controlled in real-time by our custom building management system.

Further cold containment system installations

Cold containment system in second pod beginning to enclose air filters

First floor data hall fire exit cut into building skin

A look at the custom metalwork being fitted to the fire escape opening

A look at the newly installed first floor data hall fire escape ahead of staircase installation

First floor data hall fire escape door

First louvred panel for extraction system installed on rail-side of facility

Build room workstations positioned back under power and network trunking

Wall mounted workstation monitors positioned in build room

Delivery of further cooling hardware

Delivery of further cooling hardware

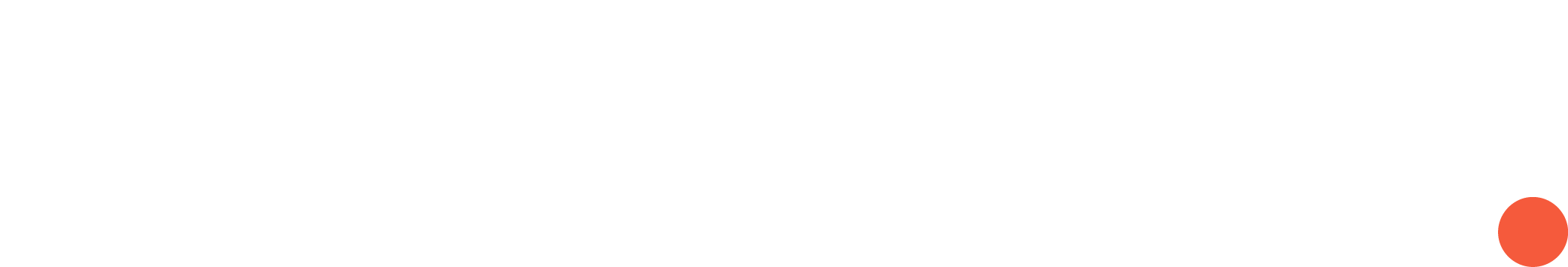

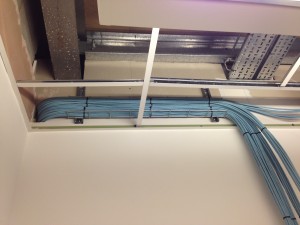

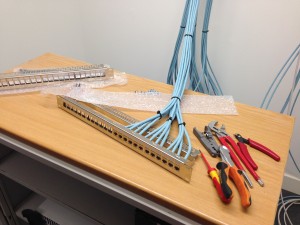

Installation of cable containment backbone arms

Installation of cable containment backbone arms

Cable containment fitted to arms in back-to-back configuration

A look at the cable containment system as it reaches down the length of the first data hall

The cable containment system reaching the lift shaft and network riser

Cable containment arms installed to end of data hall

A look at the basket bend configuration as the wall changes depth mid-data hall

Completed backbone cable containment installation

This has been a pivotal week in seeing the first data hall finally turn from a ‘semi-building site’ into a room fit for technical installations. We are very much looking forward to the weeks ahead, as the floor goes down and the racks can be positioned.