This week saw the completion of the containment systems throughout the facility, which means that all runs to hardware requiring power and/or network connectivity are now complete.

Category / Build Blog

Build Blog category, containing build progress posts for our various projects, including data centres, systems and other related tasks.

London Central Build Blog – Week 46

Again this has been a week of change across various elements of the facility, as we draw near to the stage of initial occupation.

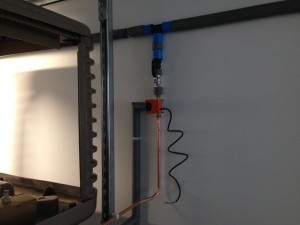

Flow controllers in place for cooler stack supplies, which will be controlled by our building management systems

London Central Build Blog – Week 45

This week saw the first of our generators land on site, which is a massive step forwards for us, and allows for the power side of the build project to begin in earnest after Christmas – essentially the final phase ahead of moving existing clients into the new site.

The arrival of the first generator sets is a big milestone for us as we head towards Christmas for a short period of well earned rest.

Our generators will always run at N+1. When at capacity, we will have 5 identical units inside of our compound, with a new unit added each time additional capacity is required to maintain the level of redundancy that we have specified.

London Central Build Blog – Week 44

This week has again seen dramatic progress as we head towards the final stage of the build, largely in the layout of the data hall ready for initial occupation early next year.

First row of cabinets in the first containment pod being bayed together, including the in-line UPS seen towards the middle

A look at the rear of the first row, with a custom solution for creating a seamless rear door surface despite the UPS being a different depth to the server cabinets

London Central Build Blog – Week 43

This week has seen major progress made in the running of final power to site services, such as lighting and control systems. This has allowed us to move off of temporary wiring setups for the first time, meaning facility-wide services now run from the core.

Although the core is still incomplete, and will form one of the final areas of the build project in the coming weeks, this is another major step towards completion.

We have also been able to move the bulk of the rack infrastructure up to the first floor data hall, ready for assembly into final positions.