Cable pulling and system commissioning is now in full swing here at the London Central facility, which is a very exciting time for our entire team. Things are coming together very quickly now, and the data centre will soon have power and connectivity flowing through it as we head into a testing phase shortly thereafter.

We took delivery of our new forklift this week, which will be employed to move heavy equipment around our campus moving forwards – it will be getting a full respray and livery soon

Final containment bridge in place, linking the first pod with the network backbone which runs across the entire data floor

Custom power distribution enclosures being built on-site

APC maintenance bypass switch for UPS being fitted with custom fabricated rack ears, for fitment into power distribution rack

Test fitting of APC maintenance bypass switch in power distribution rack

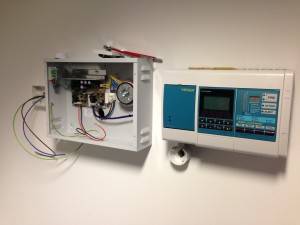

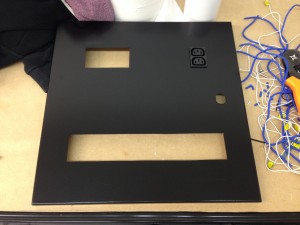

Customised door panel for power distribution enclosure, ahead of assembly

Customised door panel for power distribution enclosure, ahead of assembly

Power distribution enclosure being fitted with modified and sprayed door panels

Power distribution enclosure door panel assembly underway

Power distribution enclosure door panel assembly completed

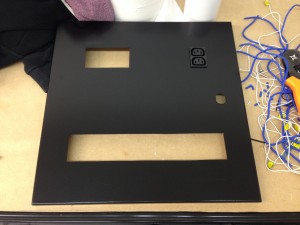

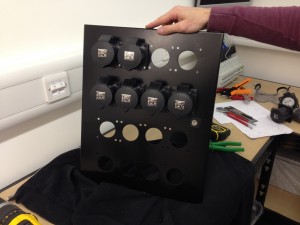

Custom built internals for power distribution enclosure

Fully assembled power distribution enclosure ahead of internal wiring and final commissioning

Containment run in place for cabling to external generators

Containment run in place for cabling to external generators

External cable ladder system being installed on generators

External cable ladder system being installed on generators

External cable ladder system joining the generator sets to the facility cladding

Cable basket affixed to generators and cladding

Basket affixed to cladding, ahead of cable exit holes and glands being cut and fitted

Final cable ladder elements being fitted

Internal generator containment spine along external cladding, ahead of cable exits being cut into the external facade

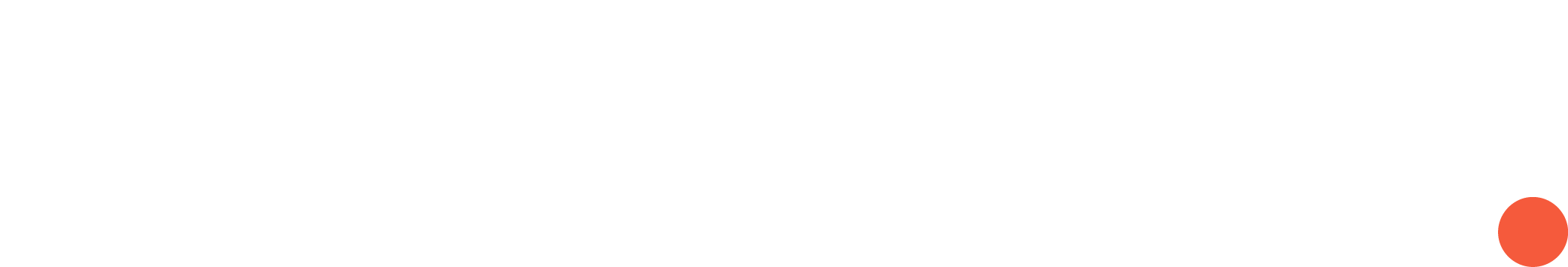

New fire alarm call points being installed throughout the facility, along with install and commissioning of centralised alarm and VESDA systems

New fire alarm call points being installed throughout the facility, along with install and commissioning of centralised alarm and VESDA systems

Ceiling void alarm notification points fitted to data hall ceiling

VESDA system and power supply units fitted to data hall entry point