This next period of work has seen the cooling system reach completion, and final works start on the data hall side of the power commissioning.

A look at the wiring of a supply fan inside one of our custom cooling stacks

The completed internals of a cooling stack control unit

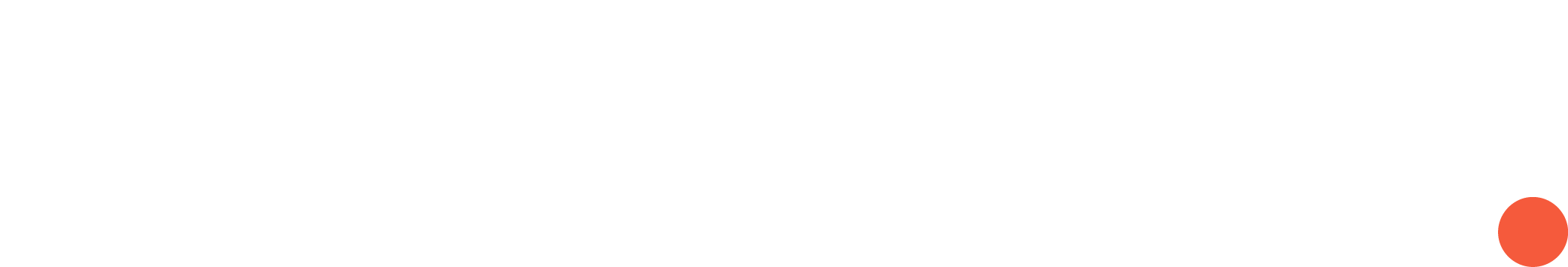

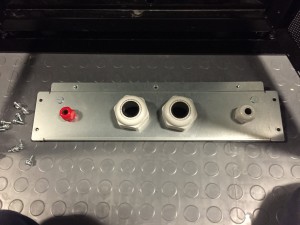

A completed cooling stack control unit with all covers fitted, ready for operation

Completed A-side cooling power distribution board, ahead of additional stacks being added modularly in the future

A look inside the now fully commissioned electrical intake room, ahead of future additions when needed

Completed termination on site-wide networking, with a temporary patch visible to liven up our front door access control unit until proper patching begins shortly

A look at in-progress fit out of the custom cooling stack control cabling as it enters the main containment backbone before heading back to the control units

A closer look at one of the louvred panel actuators

One of the water supply actuators with cabling run back to the control unit

One of the multiple environmental sensors fitted – in this case an extract air temperature sensor

A look at a wired extract fan inside of its custom duct work

A completed extract fan, safety grill and sensor assembly – more of these will be added modularly as additional stacks are introduced

Duct access hatch frame fitted for access to stack supply fans

Ceiling void recirculation ducting installed to feed recirculation chamber, which helps to regulate air temperatures inside of the facility in the winter

Flexible duct work to link ceiling grills with the recirculation chambers

3-stage high-pressure sealant applied to all duct work

Supply-side louvred panels fitted to cold corridor for external air supply

Custom modifications made to APC Maintenance Bypass Modules for our UPS systems

One of the modified bypass switches mounted in one of the distribution racks

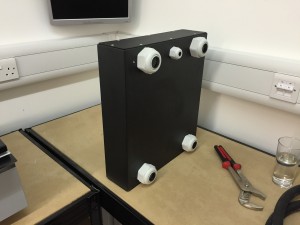

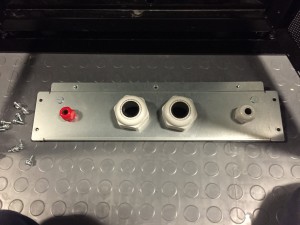

Inlet / outlet glands fitted to UPS panels, including red EPO gland and smaller control/comms cable gland

Commissioning works in progress on the UPS systems

Related